Color line

Service station over the country.

Provide relevant business resources for free overseas.

PRODUCT DESCRIPTION

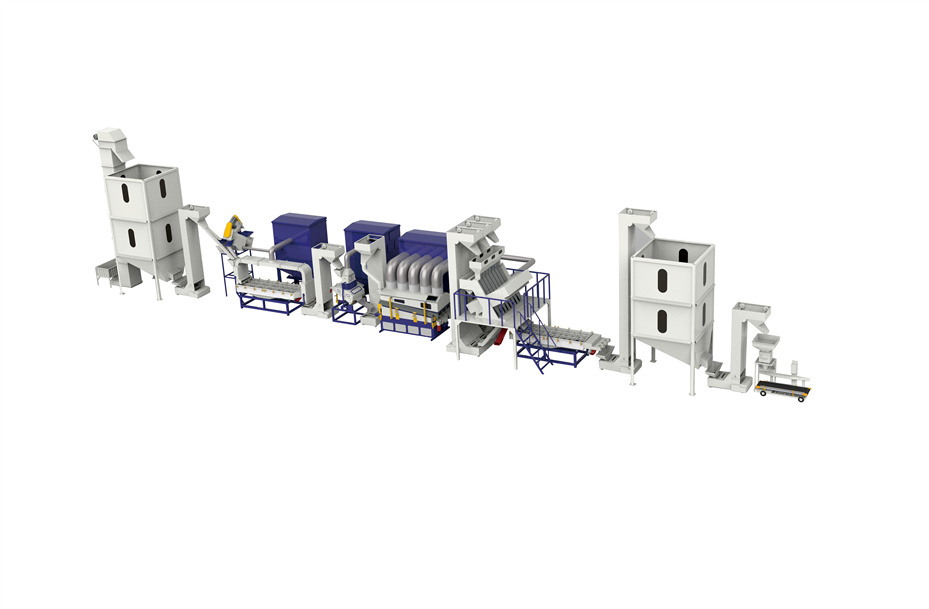

It involves a great deal of preparation to have a beautifully decorated design. We start with measuring the workshop area to get its length, width, and height, according to the entrance or exit of the workshop, we are to plan the starter in the processing line. That includes how the materials are to be fed, pit making or feeding platform, and storage tank for materials reserving or processing directly. We need to consider how many materials would you be processing. And what is the degree of quality that you need? Where is the proper place for storage of finished products? Where is the good exit for finished products transportation by truck? When all this information is gathered then we will be contributing to processing equipment.

From the first Z-type of the non-crushing elevator to the first processing machine that may either be a de-impurity or grain polisher. Then materials through the Z-type of non-crushing elevator into the de-stoner, and pass the Z-type of non-crushing elevator go to the gravity separator. They are discharging the material to the first T-type elevator of color sorter. We provide the platform of color sorter. The color sorter selects bad colored seeds by the double direction cameras, like white color seeds (scuffed seeds).

Scratched seeds, yellow color seeds, and blotch seeds. In the middle of the C-type of elevator transport, the returning or the unfinished materials in the first round are sent back to the color sorter. Then sorting the remaining materials again from the last C-type elevator, the final bad-colored seeds have been separated, and the good colored seeds go to the next vibrating grader. The quality products are ready to be collected from the vibrating grader, or additionally, they can be passed through an X-ray machine and metal detector if optimum quality is desired. The finished products can be handled by a packer, We do provide you with the supporting facilities of the packer.

In the whole production line, we have an excellent dust removal system with cyclone and pulse-jet bag filter dust collector, keeping the workshop environment clean and pleasant. The production line needs to match the air compressor and relative gas collector when using a color sorter, pulse-jet bag filter, or packer.

If we have the right opportunity, we would be truly honored to offer our service for general PLC electricity control. Still, if that's not the case, then you need to produce the general electricity control cabinet in your local market, possibly safe and convenient for you.